51

Why Walls FR?

FIRE RESISTANT

WOVENS

BOTTOMS

COVERALLS

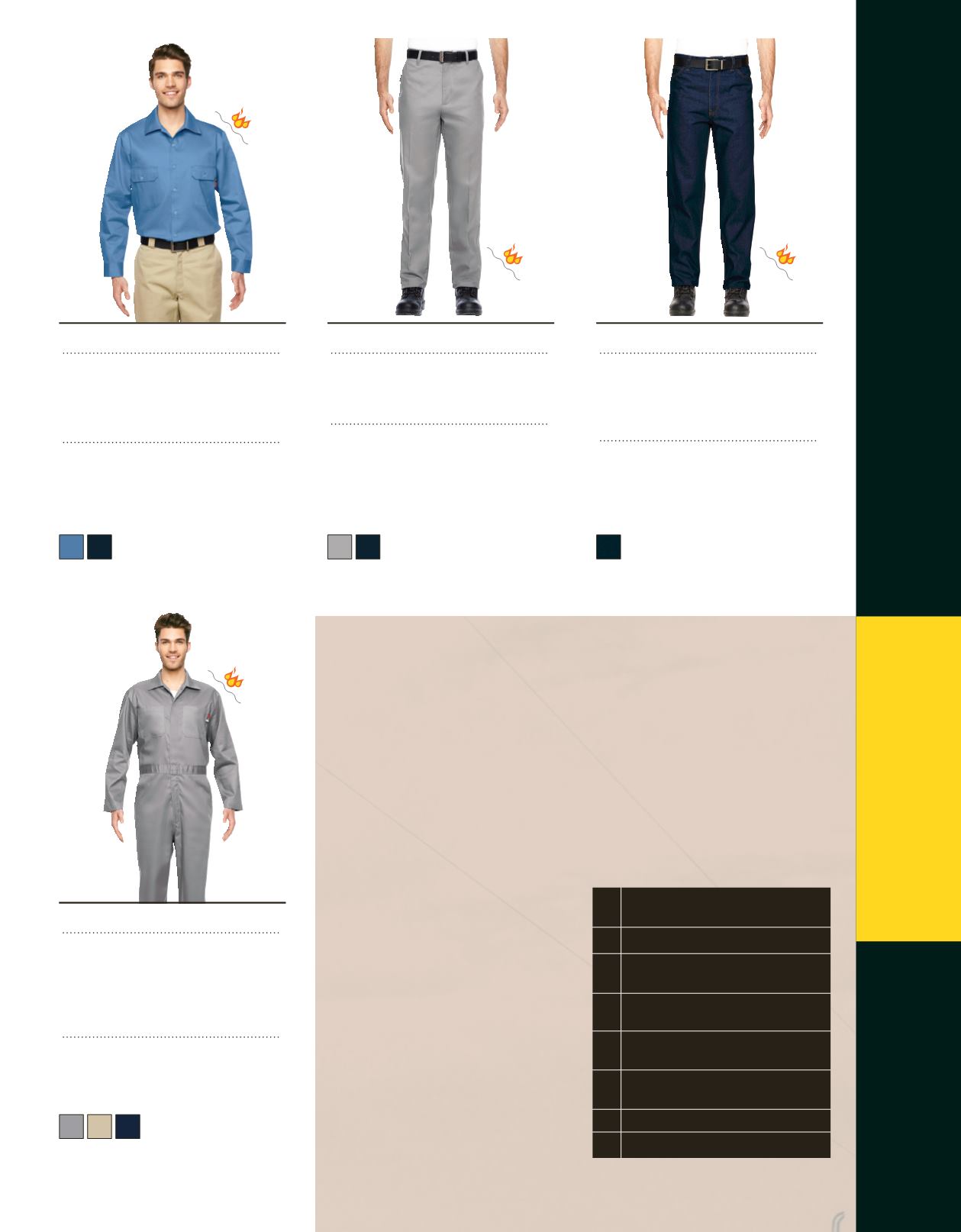

55915

$78.66

Walls FR Flame-Resistant Work Pant

• 88% cotton, 12% high-tenacity nylon twill

• pockets include two front swing pockets and

two welt hip pockets (right button closure)

Sizes:

30-44

Colors:

Gray, Navy

55395SW

$84.00

Walls FR Flame-Resistant

Five-Pocket Denim Jean

• 100% cotton flame-resistant denim

• relaxed fit with bartacks at stress points for

added strength

Sizes:

30-44

Colors:

Stonewashed Denim

62401

$92.00

Walls FR Flame-Resistant Contractor

Coverall 2.0

• 100% cotton flame-resistant twill

• bi-swing action back for ease of movement

• concealed snap closures

• two chest and two hip pockets

Sizes:

S-5XL

Colors:

Gray, Khaki, Navy

56915

$70.66

Walls FR Flame-Resistant Core Work

Shirt

• 88% cotton, 12% high-tenacity nylon twill

• two-ply back yoke

• pencil slot on left-chest pocket

Sizes:

S-5XL

Colors:

Light Blue, Navy

RICH BRAND HERITAGE

More than 75 years ago, Texas-based Walls helped

lay the foundation of workwear as we know it

today with a trademark one-piece coverall. Since

then, the Walls brand has continued to thrive in

workwear while expanding into hunting, ranch and

industrial categories.

At Walls, our long history has provided invaluable

knowledge and guiding principles that fuel our

growth, while our strong connection to the oil and

gas and utility industries has distinguished us in

flame-resistant (FR) workwear.

INNOVATION

We are committed to the continuous development

and innovation of our fabrics and designs,

exceeding the expectations of the worker, and

making safety our primary goal. Each Walls

®

FR

garment is engineered for comfort and durability to

act as a seamless extension of the working body

in motion. We are proud to know our FR coveralls

are often considered to be the “benchmark” for FR

garment comparison.

GLOBAL REACH

Increasing global demand for Walls FR products has

driven us to expand our footprint across the globe,

utilizing our industry-leading capabilities in the

international marketplace.

PROCESS & QUALITY MONITORING

Walls FR thoroughly monitors the quality of both

fabrics and its garments. This allows for consistency

in quality and a true “chain of custody” in the

production cycle. We have your back down to the

last thread.

Below are the series of steps in our production cycle

that are closely monitored:

1

Develop and approve fabric construction in

partnership with designated weaving mills

2

Monitor the quality of incoming fabric

3

ISO 9001 and UL-certified mills finish

Walls FR fabrics

4

Ensure compliance of fabric with stringent

process controls and lab testing

5

Submit fabrics, as required by authorized

bodies, to ensure up-to-date certifications

6

Selected ISO 9001-certified factories

manufacture

7

Test and certify garments

8

Ship to distribution hubs globally